Technology

At EUROstand, we deal with both production and large-format printing. Below you can find out more about the materials and technologies we are using.

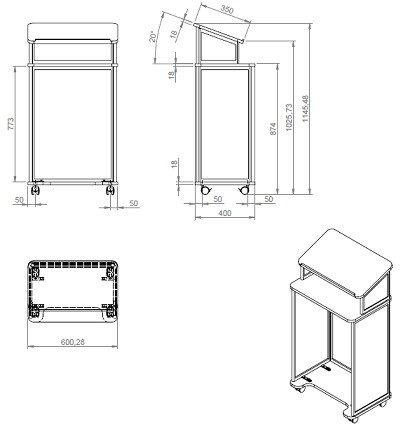

Development and production

EUROstand holds the ČSN EN ISO 9001: 2009 certificate for the development, production, and distribution of portable presentation systems. Internally, we implement complete technical drawing and production documentation, 3D models, and visualizations using the SOLIDWORKS program. This program allows us to transform our thoughts and ideas into quality products.

Construction

The base of most of our products is aluminum. This material makes it possible to produce very robust constructions that can be carried by everyone. Aluminum is anodized on the surface. The formed oxide layer improves the functional properties of the base alloy, especially increases the corrosion resistance, hardness, and abrasion resistance. Anodizing is environmentally friendly, so it does not produce heavy metals or other harmful and dangerous by-products. In places where structures are most exerted, aluminum is replaced by stainless or galvanized steel or even polycarbonate when the structures are moc complicated. Polycarbonate is characterized by high strength and toughness and it's not affected by light, heat, and does not fade or crack, ie. it is not subject to degradation even after years of use. The top plates and shelves of presentation tables are made of LDT, most often 18 mm thick with an ABS edge. ABS is an acronym for the industrial copolymer, resistant to mechanical damage, low and high temperatures, low absorbency, and harmless to health. These edges are characterized by their strength and impact resistance. They are color stable and not subject to the effects of sunlight and other light conditions.

Graphic designs

EUROstand uses the latest version of Photoshop, Illustrator, and InDesign graphic programs. Photoshop is most often used to edit bitmap graphics and high-resolution images for printing. We use Illustrator for creating and editing vector graphics. The system allows us to create logos, icons, sketches, typography, and complex illustrations for printing.

Large format printing

Our graphics department works with high-quality digital color large-format printing technologies. It uses non-aggressive Eco-Solvent Ultra inks, which excel in more faithful color rendering, increased chemical resistance, and abrasion resistance. Prints with Eco-Solvent Ultra inks are UV stable and water-resistant. Thanks to the "intelligent interweaving" printing technology, the effect of side effects are significantly reduced.

Graphic panels materials

EUROstand uses high-quality digital color printing technology, using non-aggressive Eco-Solvent Ultra inks, which excel in more faithful color rendering, increased chemical resistance, and abrasion resistance. Prints with Eco-Solvent Ultra inks are UV stable and water-resistant. Thanks to the intelligent interweaving technology, side effects are significantly reduced.

EUROstand uses several different types of materials, always based on their maximum suitability for a particular product. Below you will find an overview of the products and all the materials we use for them.

Pop-up walls straight and curved, Pop-up tables ES and ES mini, presentation tower round and square

There are two options for graphic panel materials for the products listed above.

The first option is more efficient and the quality option is polyester (PES) with floor lamination. It is a 100% opaque material that is resistant to mechanical damage and scratching due to lamination and is also resistant to fading due to the UV filter that the lamination contains. It holds the shape and plane of the wall, therefore we recommend it especially when buying our straight pop up walls, where the plane of the graphic panels is very important for the overall appearance of the presentation wall. It is also recommended for photo walls as it does not reflect camera flashes. Polyester is a strong material that allows accurate assembly and connection of graphic panels and also is dimensionally stable while printing, which means it is not affected by the heat generated by the printer.

The second, cost-effective option is PVC with matt monomeric lamination. Unlike structured lamination, monomeric lamination is smooth. PVC material is characterized by excellent whiteness. It is recommended rather for curved walls where the wall plane is less visible.

Presentation banner

We use a matt polypropylene interior banner with a thickness of 183 µm, which is a durable and resistant material that won't rip. The material provides great color rendering, which makes the graphic print look very good. The panel can be laminated for greater mechanical resistance.

Roll up, presentation banner light, Light promo wall

For these two products, we use a new generation material synthetic blockout with a thickness of 200 µm and a weight of 250 g / m2. This material is characterized by excellent flatness and minimal twisting on the sides while suspended vertically. It is suitable for the vast majority of flat presentation systems, especially roll-ups and banners. The material provides excellent print performance and is absolutely opaque. For better mechanical resistance, the panel can be laminated - a common practice with EURObanner light, where it is necessary to touch the graphic panel. Lamination is not necessary with our roll-up as the roller blind is pulled out using the aluminum profile and the graphic panel remains intact.

Aluminum promo tables EC, and exhibition dividers

Both products use 3mm Forex plates as a base and filling for the aluminum profiles. PVC Forex boards are very high quality and durable even in the outdoor environment, and have guaranteed durability in the exterior for 5 years. Forex Classic also has a B1 non-flammability certificate of the DIN 4102 standard and at the same time a European standard EN 1350-1 as C-S3, D0.

We use a matt PVC self-adhesive foil for systems with aluminum structures, mainly for EC promotional counters and dividers. The base material, which is inserted into the structures, is a 3 mm thick forex panel. The upper material is a laminated layer 180 µm thick with a scratch-resistant surface finish. This treatment ensures excellent color rendering and resistance to damage. Thanks to lamination, graphics can also be cleaned with alcohol solvents.